Contents

- Flat Wires

- Round Wires

- Braided Wires

- Rectangular Wires

- Stranded Conductors

- Specialty Conductors

- Fiberglass Insulated Wires

- Kapton® (Polyimide Film) Insulated Wires

- Polyester Film Covered Wires

- Nomex® (Aramid Paper) Insulated Wires

- Paper Insulated Wires

- Paper Insulated Multiple Wires

- Paper Insulated Stranded Copper Wires

- Cotton Covered Wires

- Enamelled Flat Wire

- Enamelled Aluminium Wire

- Copper Busbar and Copper Bars

- Busbar Connector

- Flexible Braided Copper (Busbar) Connector

- Insulated Special Production Wires & Cables

- Chopped Strand Mat

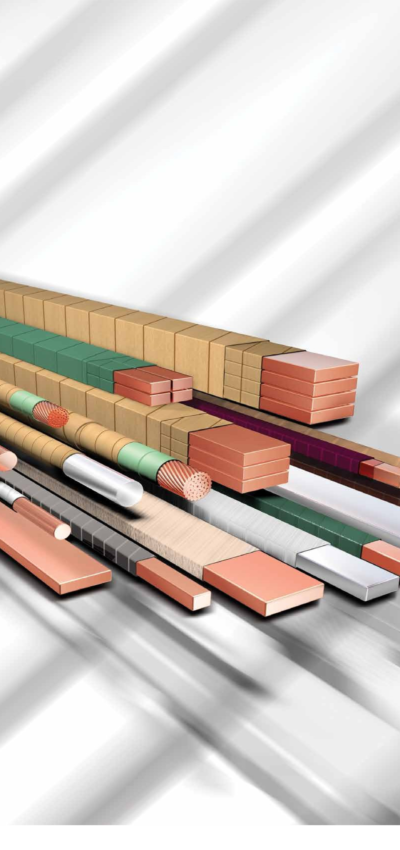

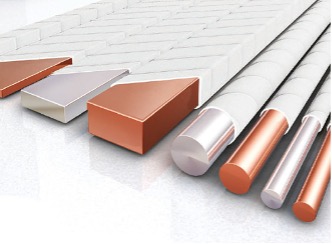

FLAT WIRES

Motor Components LTD specializes in the production of flat wires, utilizing both aluminum and copper conductors that conform to EN 13601, EN 755-2, and EN 573-3 standards. Our production range encompasses thicknesses ranging from 1.00mm to 10.00mm and widths spanning from 3.50mm to 30.00mm.

Our flat wires find extensive applications across various industries, including electric motors, lighting systems, transformers, automotive components, welding machines, generators, and traction motors. With a commitment to quality and precision, Motor Components LTD delivers reliable flat wire solutions tailored to meet the demands of diverse technological applications.

Suitable Applications

ROUND WIRES

CONDUCTORS

Aluminium and Copper

STANDARDS

EN 13601

EN 755-3 / EN 573-3

PRODUCTION RANGE

Round : Ø 1,20 – 18,00 mm

Motor Components LTD specializes in round wires made from aluminum and copper conductors, meeting EN 13601, EN 755-3, and EN 573-3 standards. Our production range spans diameters from Ø 1.20mm to 18.00mm.

These wires are utilized in various applications including electric motors, transformers, automotive components, welding machines, generators, and traction motors. With a focus on quality and reliability, our round wires ensure efficient energy transfer and dependable performance across diverse industries.

Our flat wires find extensive applications across various industries, including electric motors, lighting systems, transformers, automotive components, welding machines, generators, and traction motors. With a commitment to quality and precision, Motor Components LTD delivers reliable flat wire solutions tailored to meet the demands of diverse technological applications.

Suitable Applications

FIBERGLASS INSULATED WIRES

CONDUCTORS

Aluminium and Copper

STANDARDS

EN 60317-0-4

PRODUCTION RANGE

Thickness: 1,00 – 10,00 mm

Width: 3,00 – 30,00 mm

Round : Ø 1,20 – 10,00 mm

Motor Components LTD offers fiberglass insulated wires with aluminum and copper conductors, meeting EN 60317-0-4 standards. Our production range includes thicknesses from 1.00mm to 10.00mm and widths from 3.00mm to 30.00mm, as well as round wires ranging from Ø 1.20mm to 10.00mm.

These wires find applications in electric motors, voltage regulators, dry type transformers, UPS systems, welding machines, and electromagnetic devices, ensuring reliable performance and efficient electrical insulation across diverse industrial settings.

Suitable Applications

ENAMELLED AND FIBREGLASS INSULATED WIRES

CONDUCTORS

Aluminium and Copper

STANDARDS

EN 60317-0-4

PRODUCTION RANGE

Thickness: 1,00 – 6,00 mm

Width: 3,50 – 20,00 mm

Round : Ø 1,20 – 6,00 mm

Motor Components LTD provides enameled and fiberglass insulated wires featuring aluminum and copper conductors, adhering to EN 60317-0-4 standards. Our production range encompasses thicknesses from 1.00mm to 6.00mm and widths from 3.50mm to 20.00mm, along with round wires ranging from Ø 1.20mm to 6.00mm.

These wires are utilized across various applications, including electric motors, transformers, and generators. Engineered for reliability and performance, our enameled and fiberglass insulated wires ensure efficient electrical conductivity and insulation in critical industrial environments.

Suitable Applications

DAGLAS INSULATED COPPER WIRES

CONDUCTORS

Copper

STANDARDS

EN 60317-0-4

PRODUCTION RANGE

Thickness: 1,00 – 7,00 mm

Width: 3,00 – 15,00 mm

Round : Ø 1,50 – 15,00 mm

Motor Components LTD offers Daglas insulated copper wires, meeting EN 60317-0-4 standards. Our production range includes thicknesses from 1.00mm to 7.00mm and widths from 3.00mm to 15.00mm, as well as round wires ranging from Ø 1.50mm to 15.00mm.

These wires are essential components in electric motors and generators, providing reliable electrical conductivity and insulation for optimal performance in demanding industrial applications.

Suitable Applications

MICA COVERED WIRES

CONDUCTORS

Aluminium and Copper

STANDARDS

IEC 60317-27/IEC 60317-27

PRODUCTION RANGE

Thickness: 1,00 – 10,00 mm

Width: 3,50 – 30,00 mm

Round : Ø 1,20 – 18,00 mm

Motor Components LTD produces mica covered wires with both aluminum and copper conductors, meeting IEC 60317-27 standards. Our production range includes thicknesses from 1.00mm to 10.00mm and widths from 3.50mm to 30.00mm, as well as round wires ranging from Ø 1.20mm to 18.00mm.

These wires are extensively utilized in various applications, including high and low voltage electric motors, generators, dry type transformers, the electric and electronics industry, wind generators, electric motor maintenance and repairs, and electromagnetic devices. Engineered for reliability and performance, our mica covered wires ensure efficient electrical insulation and conductivity in diverse industrial settings.

These wires are essential components in electric motors and generators, providing reliable electrical conductivity and insulation for optimal performance in demanding industrial applications.

Suitable Applications

KAPTON® (POLYIMIDE FILM) INSULATED WIRES

CONDUCTORS

Aluminium and Copper

STANDARDS

IEC 60317-42/IEC 60317-43

PRODUCTION RANGE

Thickness: 1,00 – 10,00 mm

Width: 3,50 – 30,00 mm

Round : Ø 1,20 – 18,00 mm

Kapton® (Polyimide Film) Insulated Wires:

Motor Components LTD supplies Kapton® insulated wires with aluminum and copper conductors, meeting IEC 60317-42 and IEC 60317-43 standards. Our production range includes thicknesses from 1.00mm to 10.00mm and widths from 3.50mm to 30.00mm, as well as round wires ranging from Ø 1.20mm to 18.00mm.

These wires are widely employed in various applications, including electric motors, traction motors, the automotive industry, the aerospace industry, and relay systems. Renowned for their thermal stability, electrical insulation, and durability, our Kapton® insulated wires ensure reliable performance in demanding industrial environments.

Suitable Applications

POLYESTER FILM COVERED WIRES

CONDUCTORS

Aluminium and Copper

STANDARDS

IEC 60317-27

PRODUCTION RANGE

Thickness: 1,00 – 10,00 mm

Width: 3,50 – 30,00 mm

Round : Ø 1,20 – 18,00 mm

Motor Components LTD produces polyester film covered wires with aluminum and copper conductors, meeting IEC 60317-27 standards. Our production range includes thicknesses from 1.00mm to 10.00mm and widths from 3.50mm to 30.00mm, as well as round wires ranging from Ø 1.20mm to 18.00mm.

These wires are commonly used in applications such as transformers and UPS systems. Renowned for their electrical insulation and mechanical strength, our polyester film covered wires ensure reliable performance in diverse industrial settings.

Suitable Applications

NOMEX® (ARAMID PAPER) INSULATED WIRES

CONDUCTORS

Aluminium and Copper

STANDARDS

IEC 60317-52/IEC 60317-53

PRODUCTION RANGE

Thickness: 1,00 – 10,00 mm

Width: 3,50 – 30,00 mm

Round : Ø 1,20 – 18,00 mm

Motor Components LTD supplies Nomex® insulated wires with aluminum and copper conductors, meeting IEC 60317-52 and IEC 60317-53 standards. Our production range includes thicknesses from 1.00mm to 10.00mm and widths from 3.50mm to 30.00mm, as well as round wires ranging from Ø 1.20mm to 18.00mm.

These wires find extensive applications in transformers, including oil-immersed transformers, as well as traction motors. Renowned for their thermal stability, mechanical strength, and electrical insulation properties, our Nomex® insulated wires ensure reliable performance in demanding industrial environments.

Suitable Applications

PAPER INSULATED WIRES

CONDUCTORS

Aluminium and Copper

STANDARDS

IEC 60317-27

PRODUCTION RANGE

Thickness: 1,00 – 10,00 mm

Width: 3,50 – 30,00 mm

Round : Ø 1,20 – 18,00 mm

Motor Components LTD produces paper insulated wires with aluminum and copper conductors, meeting IEC 60317-27 standards. Our production range includes thicknesses from 1.00mm to 10.00mm and widths from 3.50mm to 30.00mm, as well as round wires ranging from Ø 1.20mm to 18.00mm.

These wires are primarily used in applications such as oil-immersed transformers and power transformers. Known for their insulation reliability and compatibility with transformer systems, our paper insulated wires ensure efficient electrical performance in critical industrial applications.

Suitable Applications

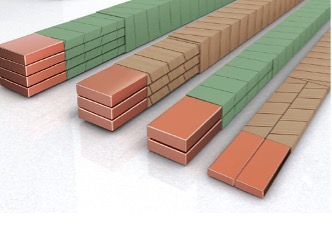

PAPER INSULATED MULTIPLE WIRES

CONDUCTORS

Aluminium and Copper

STANDARDS

IEC 60317-27

PRODUCTION RANGE

Thickness: 1,00 – 10,00 mm

Width: 3,50 – 30,00 mm

Motor Components LTD manufactures paper insulated multiple wires with both aluminum and copper conductors, adhering to IEC 60317-27 standards. Our production range includes thicknesses from 1.00mm to 10.00mm and widths from 3.50mm to 30.00mm.

These wires are primarily utilized in power transformers, where their insulation properties and multiple wire configurations contribute to efficient electrical performance and reliability. Motor Components LTD ensures the highest quality standards to meet the demanding requirements of transformer applications.

Suitable Applications

PAPER INSULATED STRANDED COPPER WIRES

CONDUCTORS

Copper

STANDARDS

IEC 60228

PRODUCTION RANGE

Thickness: 10,00 – 630,00 mm ²

Motor Components LTD specializes in paper insulated stranded copper wires, conforming to IEC 60228 standards. Our production range covers thicknesses from 10.00mm² to 630.00mm².

These wires are widely employed in critical applications such as oil-immersed transformers and power transformers. Renowned for their reliability and durability, our paper insulated stranded copper wires ensure efficient electrical performance in demanding industrial environments.

Suitable Applications

COTTON COVERED WIRES

CONDUCTORS

Copper and Aluminium

STANDARDS

IEC 60228

PRODUCTION RANGE

Round: Ø 1,60 – 10,00 mm

Motor Components LTD produces cotton covered wires with copper and aluminum conductors, meeting IEC 60228 standards. Our production range includes round wires ranging from Ø 1.60mm to 10.00mm.

These wires find applications in voltage regulators and welding machines, where their insulation properties and robust construction contribute to reliable electrical performance. Motor Components LTD ensures the highest quality standards to meet the diverse needs of industrial applications.

Suitable Applications

ENAMELLED FLAT WIRE

CONDUCTORS

Aluminium and Copper

STANDARDS

EN 60317-18

EN 60317-28

EN 60317-29

EN 60317-58

| PRODUCTION RANGE | ||

| Copper | Aluminium | |

| Thickness: | 0,80 – 4,00 mm | 1,50 – 5,50 mm |

| Width: | 3,00 – 20,00 mm | 5,00 – 16,00 mm |

| STANDARD REEL | |||

| Filling weight (kg) | Filling weight (kg) | Tara (kg) | |

| Copper | Aluminium | ||

| K500: | 90 | 30 | 7.65 |

| VM710: | 200 | 65 | 18.40 |

Motor Components LTD offers enamelled flat wire options with both aluminum and copper conductors, meeting standards EN 60317-18, EN 60317-28, EN 60317-29, and EN 60317-58. Our production capabilities include thicknesses ranging from 0.80mm to 4.00mm for copper and 1.50mm to 5.50mm for aluminum, with widths spanning from 3.00mm to 20.00mm for copper and 5.00mm to 16.00mm for aluminum.

These wires are utilized across various applications such as electric motors, generators, transformers, automotive components, motor repair and maintenance, wind generators, traction motors, power transformers, and welding machines. With a focus on quality and performance, Motor Components LTD provides reliable enamelled flat wires tailored to meet the demands of diverse industrial applications.

Suitable Applications

ENAMELLED FLAT WIRE

CONDUCTORS

Aluminium and Copper

STANDARDS

EN 60317-18

EN 60317-28

EN 60317-29

EN 60317-58

| PRODUCTION RANGE | ||

| Copper | Aluminium | |

| Thickness: | 0,80 – 4,00 mm | 1,50 – 5,50 mm |

| Width: | 3,00 – 20,00 mm | 5,00 – 16,00 mm |

| STANDARD REEL | |||

| Filling weight (kg) | Filling weight (kg) | Tara (kg) | |

| Copper | Aluminium | ||

| K500: | 90 | 30 | 7.65 |

| VM710: | 200 | 65 | 18.40 |

Motor Components LTD offers enamelled flat wire options with both aluminum and copper conductors, meeting standards EN 60317-18, EN 60317-28, EN 60317-29, and EN 60317-58. Our production capabilities include thicknesses ranging from 0.80mm to 4.00mm for copper and 1.50mm to 5.50mm for aluminum, with widths spanning from 3.00mm to 20.00mm for copper and 5.00mm to 16.00mm for aluminum.

These wires are utilized across various applications such as electric motors, generators, transformers, automotive components, motor repair and maintenance, wind generators, traction motors, power transformers, and welding machines. With a focus on quality and performance, Motor Components LTD provides reliable enamelled flat wires tailored to meet the demands of diverse industrial applications.

Suitable Applications

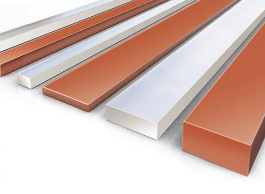

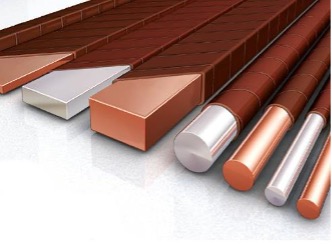

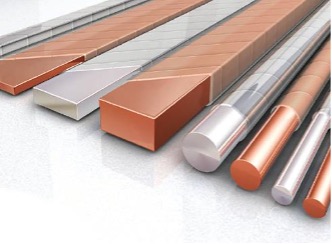

COPPER BUSBAR AND COPPER BARS

CONDUCTORS

Copper

STANDARDS

EN 13601 TS 435 / T1

PRODUCTION RANGE

Thickness : 3,00 – 20,00 mm

Width: 10,00 – 170,00mm

Round: Ø Maximum 52,00 mm

Motor Components LTD manufactures copper busbars and copper bars, conforming to standards EN 13601 TS 435/T1. Our production range includes thicknesses ranging from 3.00mm to 20.00mm and widths from 10.00mm to 170.00mm. Additionally, round options are available with a maximum diameter of 52.00mm.

These products serve various domestic and industrial applications, offering efficient electrical conductivity and reliability. Motor Components LTD ensures the highest quality standards to meet diverse industrial requirements for copper busbars and bars.

Suitable Applications

OXYGEN-FREE COPPER WIRE ROD

CONDUCTORS

Copper

STANDARDS

ASTM B170 – 99 EN 1977

PRODUCTION RANGE

Round: Ø 8,00 – 20,00 mm

Motor Components LTD manufactures copper busbars and copper bars, conforming to standards EN 13601 TS 435/T1. Our production range includes thicknesses ranging from 3.00mm to 20.00mm and widths from 10.00mm to 170.00mm. Additionally, round options are available with a maximum diameter of 52.00mm.

These products serve various domestic and industrial applications, offering efficient electrical conductivity and reliability. Motor Components LTD ensures the highest quality standards to meet diverse industrial requirements for copper busbars and bars.

Suitable Applications

ENAMELLED ALUMINIUM WIRE

CONDUCTORS

Aluminium

STANDARDS

IEC 60317 – 25

PRODUCTION RANGE

Round: Ø 0,14 – 4,25 mm

Thermal Class: Thermal Class 200

Motor Components LTD produces enamelled aluminium wire in compliance with IEC 60317-25 standards. Our production range covers round wires with diameters ranging from Ø 0.14mm to 4.25mm, designed for a thermal class of 200°C.

These wires find applications across various industries due to their excellent electrical conductivity and thermal stability. Motor Components LTD ensures the highest quality standards to meet diverse industrial requirements for enamelled aluminium wire.

Suitable Applications

BUSBAR CONNECTOR

IEC 60228 – EN 12449

Motor Components LTD manufactures busbar connectors adhering to standards IEC 60228-EN 12449. Our production range includes thicknesses ranging from 1.00mm to 10.00mm and widths from 6mm to 400mm. These connectors are designed for a thermal class of 200°C.

Busbar connectors serve various applications due to their versatility and reliability in electrical connections. Motor Components LTD ensures top-notch quality to meet diverse industrial requirements for busbar connectors.

Suitable Applications

INSULATED SPECIAL PRODUCTION WIRES & CABLES

IEC 60228 – EN 12449 /

Motor Components LTD produces flexible braided copper (busbar) connectors in accordance with standards IEC 60228-EN 12449 and IEC 61439. Our production range includes thicknesses ranging from 1.00mm to 10.00mm and widths from 6mm to 400mm. These connectors are designed for a thermal class of 200°C.

Renowned for their flexibility and reliability, flexible braided copper connectors serve various applications in electrical systems and are essential for ensuring efficient power distribution and connectivity. Motor Components LTD ensures top-notch quality to meet diverse industrial requirements for flexible braided copper connectors.

Suitable Applications

FLEXIBLE BRAIDED COPPER (BUSBAR) CONNECTOR

IEC 60228 – EN 12449 /

Motor Components LTD produces flexible braided copper (busbar) connectors in accordance with standards IEC 60228-EN 12449 and IEC 61439. Our production range includes thicknesses ranging from 1.00mm to 10.00mm and widths from 6mm to 400mm. These connectors are designed for a thermal class of 200°C.

Renowned for their flexibility and reliability, flexible braided copper connectors serve various applications in electrical systems and are essential for ensuring efficient power distribution and connectivity. Motor Components LTD ensures top-notch quality to meet diverse industrial requirements for flexible braided copper connectors.

Suitable Applications

INSULATED SPECIAL PRODUCTION WIRES & CABLES

CONDUCTORS

Copper and Aluminium

STANDARDS

IEC 60317 – 25

PRODUCTION RANGE

Round: Ø 0,14 – 4,25 mm

Thermal Class: Thermal Class 200

Motor Components LTD specializes in the production of insulated special production wires and cables, featuring copper and aluminium conductors compliant with IEC 60317-25 standards. Our production range encompasses round wires with diameters ranging from Ø 0.14mm to 4.25mm, designed for a thermal class of 200°C.

These specialized wires and cables are engineered to meet specific industrial requirements, ensuring optimal electrical performance and reliability in various applications. Motor Components LTD prioritizes quality and precision to deliver tailored solutions for diverse industrial needs.

Suitable Applications

CHOPPED STRAND MAT

PRODUCTION RANGE

Weight per unit: 600mg/m2

Width: 1250 mm

Type/Grade: Glass E

Motor Components LTD offers chopped strand mat with a production range including various weight per unit options, with a standard starting point at 600mg/m2. The width of our chopped strand mat is 1250mm, and it belongs to the Glass E type/grade.

Additional weight per unit options may vary depending on specific customer requirements and application needs, ensuring versatility and flexibility in meeting diverse industrial demands.