Overview

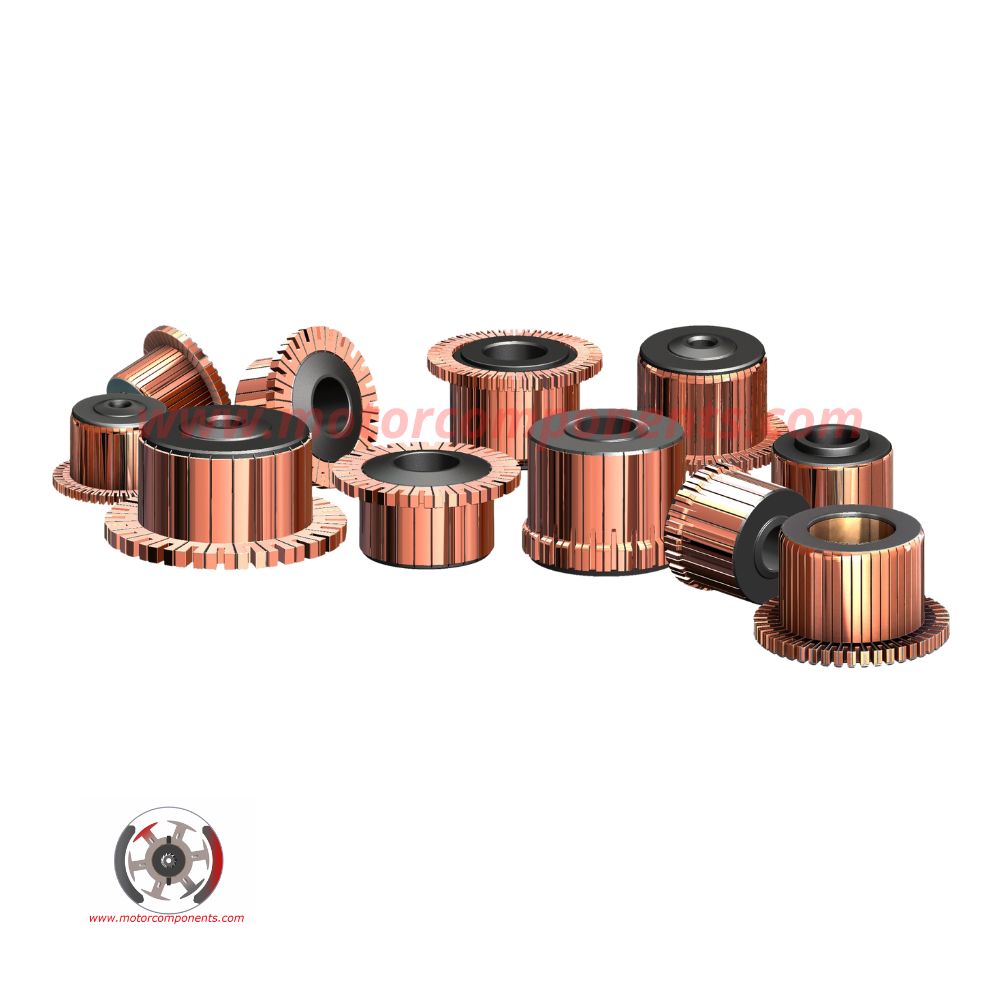

COMMUTATORS is a premier product in the electric motor manufacturing industry, specifically designed for a variety of applications, including industrial machinery, automotive, and consumer electronics.

A commutator is an arrangement of insulated copper segments (bars) that are connected to coils of an electric motor to provide a reversal of current into the coils of the motor.

The assembly is insulated on the rotor shaft and the copper blades are connected to the anchor windings. Permanently installed carbon brushes make contact with the collector and provide power to the anchor windings.

| Our product line includes most common types of commutators used in today’s industrial applications and they can be grouped as; hook type, barrel and planer (face type) types of commutators. These are also constructed with several different methods of manufacturing mostly depending on application criteria and design of the motor. With over 50+ years’ experience in the industry, we offer approx. 800 types of commutators with OD 4mm up to 385mm moulded type of construction and custom made (handcrafted) commutators for larger machines with steel and mica construction. The rage for this type of had crafted commutators is OD from 50mm up to 1400mm. Our slip ring range between 25mm ~ 400mm. Using only the best material and product design, we have the experience to offer commutators and slip rings for the most demanding specifications of high speed and high-temperature applications; especially for the automotive, power tool, home appliance and industrial DC motor applications. For your obligation free quotation, send us your technical drawings, specifications, or samples. |

Applications and Industries

The COMMUTATORS is suitable for use across multiple industries such as automotive, aerospace, and other electric motor manufacturing industries.

- Automotive Applications

- Home appliances

- Power tools

- Industrial motors and pumps

- EV industries

- Aeronautical and Marine

Customization by Motor Components LTD

Motor Components LTD offers extensive customization options for the COMMUTATORS to meet the specific needs of our clients. With precision engineering, we tailor the product to your exact specifications, ensuring optimal performance and integration.

Precision Manufacturing Engineered for High-Quality Stampings

MotorComponents Ltd excels in precision manufacturing, specializing in the production of high-quality stampings. Our comprehensive capabilities cover every phase of the manufacturing process, ensuring exceptional precision and craftsmanship in all our engineered components.

In-House Expertise and Advanced Tool Design

With a dedicated in-house team of skilled professionals, including tool designers, engineers, and technicians, we have the expertise to deliver outstanding results. From the initial concept to the final product, our experts collaborate closely with you to bring your ideas to life. Our advanced tool design capabilities enable us to create custom tools that precisely meet your specifications, ensuring optimal performance and accuracy.

Seamless Transition from Concept to Mass Production

At MotorComponents, we offer a seamless transition from concept to mass production. Our capabilities include sample and prototype development, allowing you to refine your design before moving into full-scale manufacturing. With efficient and streamlined processes, we ensure rapid turnaround times and cost-effective production, without compromising on quality.

State-of-the-Art Facility and Cutting-Edge Machinery

Equipped with a state-of-the-art facility, our manufacturing plant boasts a wide range of advanced machinery and technologies. Our arsenal of high-speed pressing machines, ranging from 60T to 450T, allows us to handle various production needs. Additionally, our facility is equipped with CNC lathes, slitting machines, mechanical presses, milling machines, grinding machines, punching machines, EDM wire cutting machines, drilling machines, die casting machines, gas-nitriding furnaces, carburizing equipment, high-frequency heat treatment machines, powder coating capabilities, and an array of testing instruments. These cutting-edge technologies empower us to deliver precision, accuracy, and superior quality in every stamped component we produce.

Uncompromising Commitment to Quality Control

MotorComponents maintains an unwavering commitment to quality control throughout the manufacturing process. Our team adheres to stringent quality control measures, ensuring that each component meets or exceeds industry standards. From material selection to final inspection, we employ rigorous testing and inspection methods to guarantee the highest level of quality and reliability in our stampings.

Broad Industry Applications

With our extensive capabilities, MotorComponents caters to a wide range of industries and applications. Whether you require intricate and complex stampings for automotive, aerospace, electronics, or any other industry, we have the expertise and resources to meet your specific manufacturing needs.

Trust in MotorComponents for Precision Manufacturing

Choose MotorComponents Ltd for precision manufacturing engineered for high-quality stampings. Our skilled team, advanced facility, and unwavering commitment to excellence ensure that we deliver superior products that meet your exact specifications. Experience the difference that precision manufacturing can make in your components and partner with us for your stamping needs.